金属镀层微粒子 Micropearl™

- 首页

- 微粒子【Micropearl™】

- 金属镀层微粒子 Micropearl™

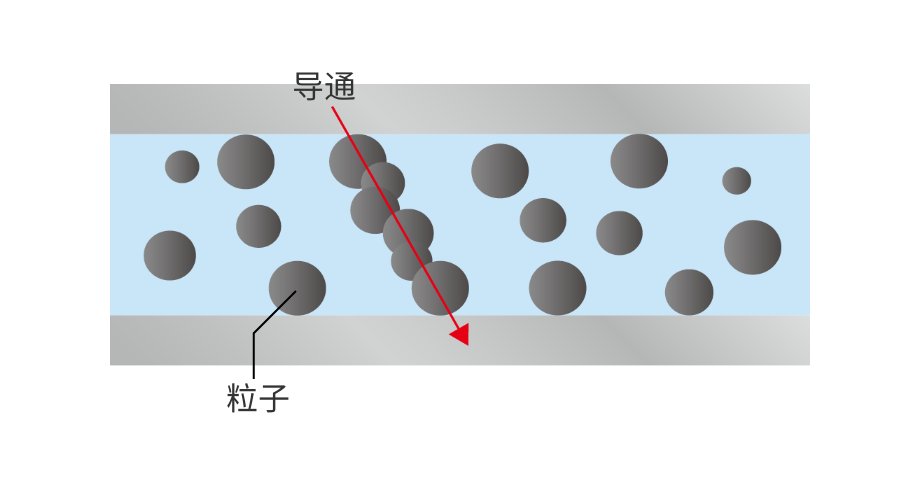

ACF(各向异性导电膜)组成材料

课题

随着智能手机和电视等显示设备的高精细化,近年来为了实现全面显示,进行了窄边框、可折叠、可弯曲柔性屏幕等设计,这些设计需要实现更小型化和精细化的元件。

实现这些目标的是使用 ACF 进行组装,并且使用的导电粒子必须具备更高的品质。

SEKISUI's Solution

- 具备从柔软到硬性材料等广泛且精细的粒径选择,能提供最符合客户需求的提案。

- 从树脂颗粒到最终产品的一体化制造,实现高度定制化与品质保证。

- 除了基材粒子和镀层以外,还拥有各种独特技术,对提供导通信赖性与各向异性导电性能的提升有所贡献。

积水化学的 ACF 用导通填充材料市场占有率为业界第一名。

- 公司内部统计资料

电气导通与接合可靠性机制

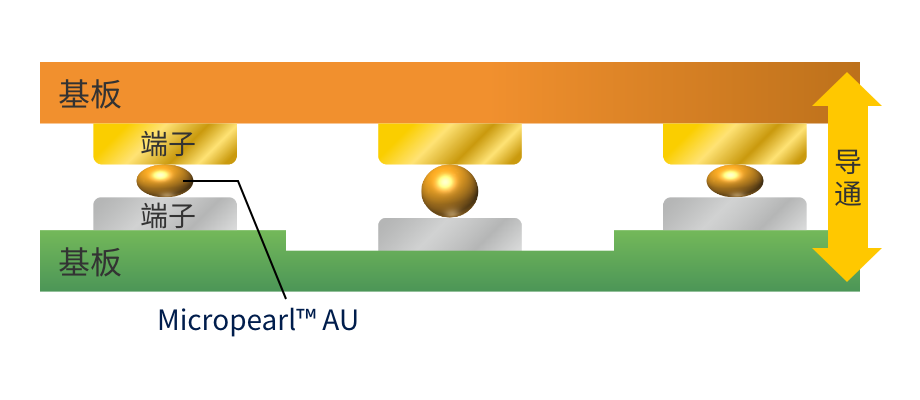

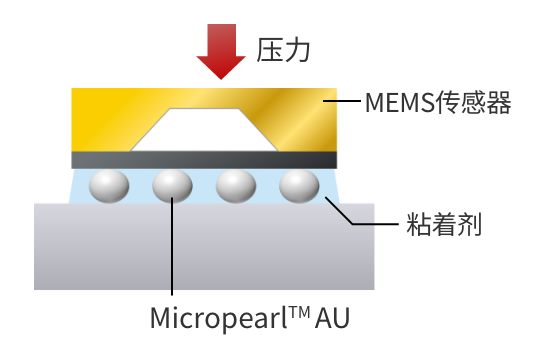

金属镀层微粒子 Micropearl™ AU 的回弹力与粘结剂的收缩力使其能与电极接触且密合,进而稳定电气导通。

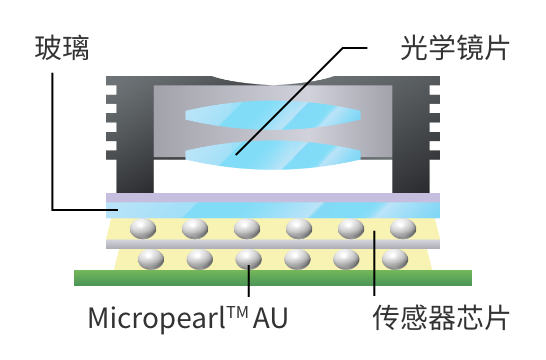

可轻松均匀地控制粘合层、液体层及所需空间的厚度

预期效果

能够保证平整度和平行性,抑制自硬化收缩引起的变形(提升可靠性)/防止光学轴偏移/均匀散热/提升应力分散传感器的灵敏度等。

例如:叠层芯片/光学元件/传感器/液晶材料/通信模块相关元件粘合/玻璃粘合等。

作为电磁波屏蔽材料

课题

随着汽车的安全性要求提升和自动驾驶技术的发展、ADAS 先进驾驶辅助系统的搭载数量和 EV 电动汽车的普及化,预计各种控制系统的数量都会增加。然而,这些系统之间的电磁干扰可能会造成性能下降或系统停机,这已被视为重大风险。

为此,将电磁波屏蔽功能集成到树脂外壳中将变得更为常见,但例如从制作普通树脂外壳后再进行金属涂层的方法,可能会增加制造步骤并导致车辆重量增加。

SEKISUI's Solution

- 通过将具有导通性的金属镀层微粒子 Micropearl™ AU 混入成型前的树脂中,仅需进行常规成型,即可实现电磁波屏蔽效果。

- 使用比重较低的金属镀层微粒子 Micropearl™ AU,可轻松分散于树脂中,并有助于减少车辆重量。

异种材料导通接合

课题

近年来,对异种金属或各种材料进行接合的需求日益增加。

特别是当需要在维持金属间导通的情况下进行大面积接合时,通常需要较强的力或热,这可能会导致薄金属箔破裂或出现针孔。

因此,作为简便的接合方法,市面上出现了导电粘合剂,但这也带来了厚度控制困难、需要添加大量填料来确保导通的问题。

SEKISUI's Solution

- 通过添加与目标膜厚度相当的均匀金属镀层微粒子 Micropearl™ AU,预期能以最低添加量达到最稳定的上下导通。

- 由于添加量较少,能维持粘合力和成型性。

- 通过适当设置添加量,预期还能提供间隔功能。

- 由于比重较低,能够轻松实现均匀分散。

进行上下导通示意图

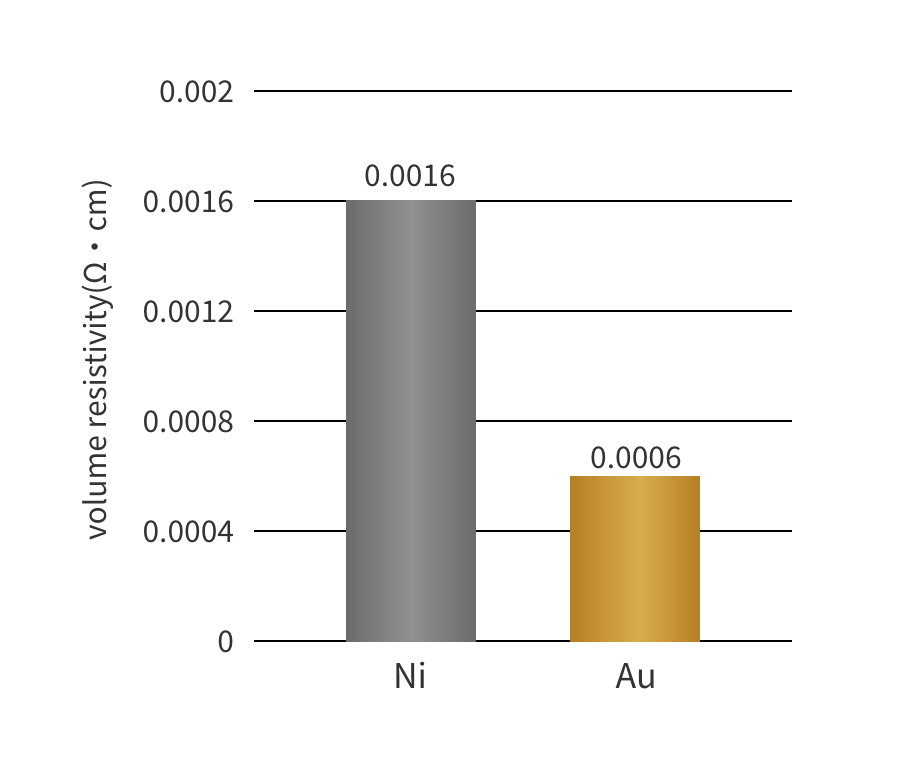

金属种类选择

代表性金属种类

Ni鎳

- 特点

-

- 硬质金属

- 强磁性

Au金

- 特点

-

- 高可靠性

若您有其他金属的镀层需求,

欢迎随时与我们联系。

- 颜色仅供参考,实际颜色可能有所不同。

不同硬度的回弹率比较

可以通过控制树脂粒子和金属膜调整硬度和回弹率。

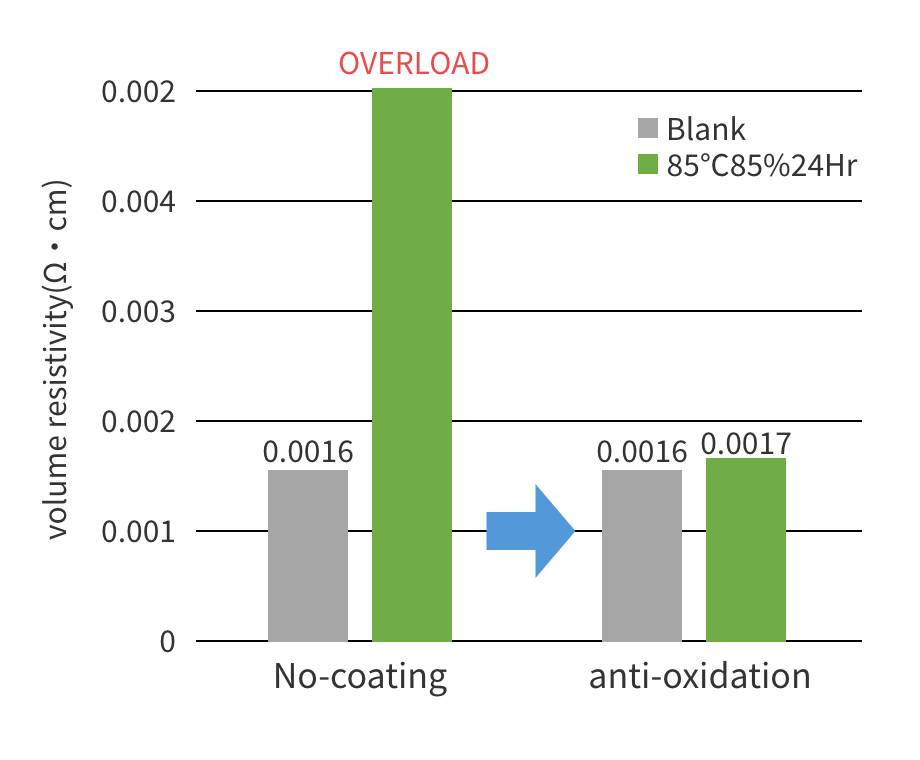

体积电阻比较

Ni镍镀膜的防锈处理效果

- 树脂核心 10μm 的验证参考值。

- 以上为参考值,粒径与金属膜厚度会有所变化。